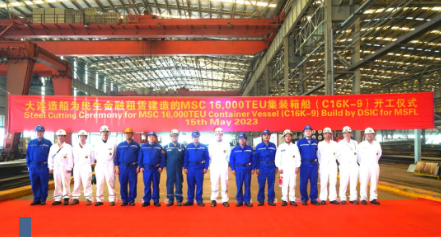

DSIC Tianjin's first 16,000TEU container ship

Recently, the No. 9 16,000TEU container ship built by Dalian Shipbuilding, a subsidiary of China State Shipbuilding Corporation, for MSC Mediterranean Shipping Co., Ltd. started construction at Tianjin base. The ship is the first LNG dual-fuel powered 16,000TEU container ship built by DSIC Tianjin.

The total length of the ship is about 366 meters, the molded width is 51 meters, and the molded depth is 30.2 meters. It can carry 16,196 standard containers. The main engine is equipped with iCER-Diesel green energy-saving system, and the auxiliary generator is equipped with a low-pressure SCR system, which meets Tier III nitrogen oxide emission requirements. The ship's main engine, auxiliary generator sets, and auxiliary boilers are all equipped with dual fuel supply systems, which can burn low-sulfur fuel oil and LNG gas fuel to meet the emission requirements of sulfur oxides. The B-type LNG fuel tank is independently designed and built by Dalian Shipbuilding, with independent intellectual property rights. At the same time, it is equipped with various energy-saving equipment such as an air lubrication drag reduction system, a shaft generator, and an energy-saving guide wheel in front of the propeller.

Out of the dock!

The first 13000TEU dual-fuel container ship

On May 15, the first 13,000TEU dual-fuel container ship (H1839A) built by Hudong Zhonghua, a subsidiary of CSSC, was successfully undocked. The project has a total of six 13,000TEU dual-fuel container ships. At present, the first ship is out of dock. The No. 2 ship is built in the No. 3 dock. The fuel tank of the No. 4 ship is about to be docked. Day to complete work.

The 13,000TEU dual-fuel container ship is the second type of dual-fuel container ship undertaken by the company after the 23,000TEU dual-fuel container ship. The ship is the latest generation of green, environment-friendly, high-efficiency and energy-saving container ships in the world. It adopts the Mark III liquid cargo containment system. After completion, it will be the largest dual-fuel container ship operating on the South American route. The main engine of the ship has been upgraded and adopts a new generation of global Intelligent Controlled Exhaust Gas Recirculation (ICER) system, which can reduce methane escape by 50% in gas mode and reduce greenhouse gas emissions by more than 28%.

deliver!

Domestic new 24,000 DWT crude oil carrier

On May 16, the naming and delivery ceremony of the 24,000DWT crude oil tanker "Changxiangzhou" built by Wuchang Shipbuilding, a subsidiary of CSSC, for China Merchants Nanyou was held.

This type of ship was designed in detail by the 708th Institute. It is a crude oil tanker suitable for inland rivers and near and far seas. It is also the largest deadweight tonnage crude oil tanker in Central China currently under construction by Wuchang Shipbuilding. Both "Changxiangzhou" and the previously delivered sister ship "Changjizhou" are new types of green, low-carbon and environmentally friendly crude oil transportation ships developed in China, which meet the latest CCS green ecological ship regulations. This type of ship adopts China Chuanchai large-scale marine diesel engine, equipped with domestic self-designed energy-saving devices, and preset LNG fuel system; the degree of automation is high, and it is equipped with a visual intelligent operation and maintenance system, which fully meets the classification society's intelligent energy efficiency management and fire prevention , Hazardous area equipment layout requirements.